ceramic hardness testing|hardness of ceramic materials : distribute Hardness testing is another key aspect of ceramic testing methods. It measures a ceramic’s resistance to indentation or scratching. The results of hardness tests are important . Dínamo Kiev; Dynamo 2 Kiew; Dinamo Kiev II; Dynamo Kyiv U19; Dynamo Kiew U17; Dynamo 3 Kyiv; Dynamo Kyiv UEFA U19; Plantel Dínamo Kiev - Selecionar temporada : Compacto. Tabela completa. Galeria # Jogadores Idade Nac. . Valor de mercado ø-Valor de mercado : Goleiro: 24,33:

{plog:ftitle_list}

27 de jun. de 2023 · 1 – Faça o download do jogo. 2 – E em seguida instale o aplicativo. INFORMAÇÕES DO MOD. MOD MENU: IMORTALIDADE. OURO INFINITO. VOAR. SUPER PULO. SUPER VELOCIDADE. NOTA: .

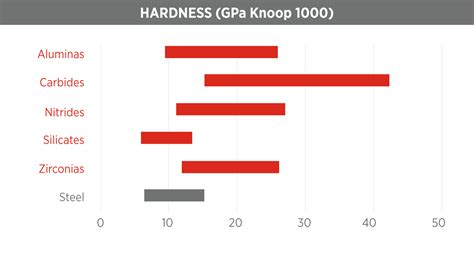

Hardness testing is another key aspect of ceramic testing methods. It measures a ceramic’s resistance to indentation or scratching. The results of hardness tests are important .The hardness of Fine Ceramics is generally indicated using a Vickers hardness number. The method for measuring the hardness of Fine Ceramics is defined in JIS R 1610 (ISO 14705: 2000). Vickers hardness is a resistance value .Hardness is one of the most frequently measured properties of a ceramic. Its value helps to characterize resistance to deformation, densification, and fracture. Hardness is crucial for . Vickers hardness of ceramics usually decreases with increasing indentation size or indentation force, as shown in Fig. 1. The trend is known as the indentation size effect .

Hardness of ceramics is determined by their chemical compositions and microstructure characteristics: porosity, grain size, grain-boundary phases. Depending on the loading . An overview of hardness testing of ceramics is presented. Conventional test methods are discussed, particularly with respect to major sources of experimental error and . Very popular tests of ceramics are the various hardness tests (for example Vickers hardness test), which is not only a cost saving test, but also requires shorter times, since no .Hardness testing is particularly important to prove the mechanical strength of ceramic work pieces which are highly affected by wear; typical examples are friction bearings, brake disks or .

Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the .

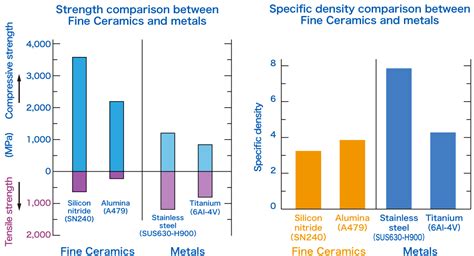

strength of fine ceramics

Mohs hardness test: When conducting the test, place the unknown specimen on a table top and firmly hold it in place with one hand. Then place a point of the reference specimen against a flat, unmarked surface of the unknown .But the substrate becomes an overriding factor when testing thin films, these coatings are usually less than 5 microns and there is no-way you would get a reading of the film hardness. You are testing the hardness of the steel underneath the coating.Hardness is also considered as a measure of the wear and fatigue of a material. Hardness and its testing are the focus of materials science and solid state physics and is measured in fracture toughness and is thus clearly one of the material properties. A hardness test of mineral substances can be determined by different methods.computed on the basis of the crack lengths, the indentation load, the hardness, the elastic modulus, the indentation diagonal size, and an empirical fitting constant. This method has the appeal that it uses conventional hardness equipment, uses a very small test piece, and does not require elaborate precracking or testing equipment.

Request PDF | Hardness and Non-Destructive Testing (NDT) of Ceramic Matrix Composites (CMCs) | This article presents a short overview of the most common techniques in non-destructive testing (NDT .In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as .

Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5)How do you test ceramic hardness? There are several methods you can use to test the hardness of ceramic materials, including indentation, scratch, and rebound tests: Indentation test. The indentation test involves pressing a small indenter into the surface of the material and measuring the depth of the resulting indentation. The hardness is .Materials Chemistry and Physics, I 7 (1987)46 461 l-473 HARDNESS TESTING OF CERAMIC MATERIALS* D.J. CLINTON and R. MORRELL Division of Materials Applications, National Physical Laboratory, Teddington, (U.K.) ABSTRACT This paper reviews the applicability of hardness test methods to polycrystalline ceramics. It is concluded that Rockwell .

Contrary to the ceramic coating myths circulating on the internet, these automotive protectant products are graded on the “Wolff-Wilborn” pencil hardness scale, and NOT the Mohs scale. A topic that we will discuss in greater detail a bit later. Grading a pencil’s hardness level revolves around applying controlled amounts of pressure to a surface with a .Every effort should be made to standardize the hardness of the lead used and the technique followed. It is also important to note that the pencil hardness test is only one of many tests used to evaluate coatings. There is more than the hardness of any coating to be considered, so do not judge a finish entirely on the basis of its hardness. Materials Chemistry and Physics, ./7 (1987) 461-473 461 HARDNESS TESTING OF CERAMIC MATERIALS* D.J. CLINTON and R. MORRELL Division of Materials Applications, National Physical Laboratory, Teddington, (U. K.) ABSTRACT This paper reviews the applicability of hardness test methods to polycrystalline ceramics. It is concluded that Rockwell .

American Education Hardness Collection with Test Kit Rating Conclusion. To wrap it up, the Mineral testing kit (Amazon link) is the industry and Rockhound premium standard because it is exact and easy to carry with . The actual indentation response of the ceramic material tested must be considered before selecting the appropriate hardness technique and test force. There is no significant difference between the abilities of the hardness techniques HV1, HK2, and HR45N to discriminate sensitively between materials of closely similar properties.

hardness of ceramic materials

Figure 7.2 demonstrates the equipment for the micro Vickers hardness test which is available in various atmospheres from room temperature to high temperature region over 1000 °C. Figure 7.3 [] shows the temperature dependence of the micro Vickers hardness of various ceramics measured using this equipment in vacuum.The micro Vickers hardness of Ni alloy .

In 1994, the National Institute of Standards and Technology commenced a project for SRM2830, Knoop Hardness of Ceramics. The ceramic is a hot isostatic pressed silicon nitride block that was .

Ceramic & Porcelain Tile Testing Methods and Results Explained. www.creativematerialscorp.com | 800.207.2967 Abrasion Stage at Which the Failure is Visible Class 100 Class 0 . tool that can be used to determine the hardness of either the surface glaze, or the tile body itself.Hardness testing of ceramics is done to check the mechanical strength of ceramics used in these applications. Whether we use the Vickers or Knoop hardness test methods, the size or depth of indentation caused by an indenter (typically diamond material) on the material being tested is measured as the hardness value of the material. .Title: Challenges of hardness testing on ceramic materials Author: QATM Subject: The advanced optic system quality with Qness 60 EVO series and Qness 200 series hardness testers eases daily hardness testing on ceramic material samples or even working with parts with ceramic coatings depending on the surface finish and magnification automatic image . The Purpose of Hardness Testing for Ceramic Coatings. The mechanical property of a material’s hardness is defined as a specific and calculable measure of how resistant a material is to compressive force. Hardness is a representation of a material’s resistance to localised plastic deformation.

In this work, the influence of crack forms [radial crack (RC) and half-penny crack (HPC)] on indentation hardness test results of ceramic materials (W e/W t = 0.3–0.7) was studied by finite element analysis and verified by experiments. Excluding the influence of size effect, the values of HPC and RC indentation hardness from instrumented indentation tests on .

Porcelain is a ceramic material made by heating materials, generally including a material like kaolin, in a kiln to temperatures between 1,200 and 1,400 °C. . The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials .Hardness characterizes the resistance of the ceramic to deformation, densification, displacement, and fracture. It is usually measured with conventional microindentation hardness machines using the Knoop or the Vickers diamond indenters.JIS R 1610 Testing Method for Vickers Hardness of High Performance Ceramics5 2.4 ISO Standard: ISO 6507/2 Metallic Materials—Hardness test—Vickers test—Part 2: HV0.2 to less than HV5 6 3. Terminology 3.1 Definition: 3.1.1 Vickers hardness number (HV), n—an expression of hardness obtained by dividing the force applied to a Vickers

Mohs hardness kit, containing one specimen of each mineral on the ten-point hardness scale. The Mohs scale (/ m oʊ z / MOHZ) of mineral hardness is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material.. The scale was introduced in 1812 by the German geologist and mineralogist .

do ceramics have high hardness

ceramic tiles density kg m3

Vazou Aqui - Amiichan. Derrubaram nosso canal, criei outro e já repostei tudo aproveitem entrar que agora tem o vip .

ceramic hardness testing|hardness of ceramic materials